By James J. Hodl

Pinal Nugget

For more than a century, Hayden and copper smelting have been synonymous. In fact, Hayden started as essentially a company town providing housing for workers at the nearby Ray open pit mining complex and the local copper smelter complex. Both Hayden and the copper smelter came into being in 1912.

And the relationship will continue into the future, according to Thomas Aldrich, vice president of environmental affairs at ASARCO/Grupo Mexico, which owns and operates the Hayden Smelting Operations. Copper reserves remain high at the Ray and Mission mines that send ore to the smelter. And ASARCO is embarking on a project to upgrade the smelter so that it meets new environmental emission standards, and thus continues to provide jobs and economic prosperity to Hayden and the surrounding Copper Basin area.

The ASARCO smelter and surrounding operations continue to be an important part of the Hayden/Winkelman economy. It employs 1,400 hourly and salaried workers, who are annually paid $140.8 million in wages, salaries and fringe benefits. The operations also generate $28.6 million in property, severance and sales taxes. The company annually generates spending of $345.8 million on materials, fuel and supplies into the Arizona economy.

Each year the Hayden smelter produces more than 300 million tons of 99 percent pure copper used in numerous household and commercial products, according to Kelly Norton, president of the Arizona Mining Association. The smelter also produces more than 575,000 short tons of sulfuric acid each year.

From the beginning, the smelter has emitted into the air byproducts that include lead, arsenic, sulfur dioxide (SO2), particulate matter, and other materials. These contaminants drifted over the entire region in the air and many of the materials contained in these emissions fell out of the atmosphere and settled on the ground.

Less than a decade after the Hayden smelter began operations, the first emission controls were installed. The electrostatic precipitators added in 1920 were designed to remove particulate matter from the stack emissions. These minimal emission controls remained the only controls until 1969 when anticipation of new federal requirements being offered to the Clean Air Act prompted the installation of acid plants to more effectively limit SO2 emissions.

In 1974, the 1,000-foot double-shell concrete stack was built by ASARCO to discharge exhaust gases from the smelting operations, which replaced the 300-foot reverberatory furnace stack and 250-foot converter stack. ASARCO further modernized Hayden smelter in 1983 by constructing of a second sulfuric acid plant to capture and reuse SO2 emissions produced during smelting, and construction of a wastewater treatment plant to recover process water from the sulfuric acid plant for reuse.

The last major renovations took place in 1989 and 1996. In 2012, ASARCO voluntarily undertook a $10 million project to reduce lead emissions through the addition of a monitor system to keep lead emissions to within EPA rules issued in 2008 that trimmed allowable emission levels to one-tenth of the former standard.

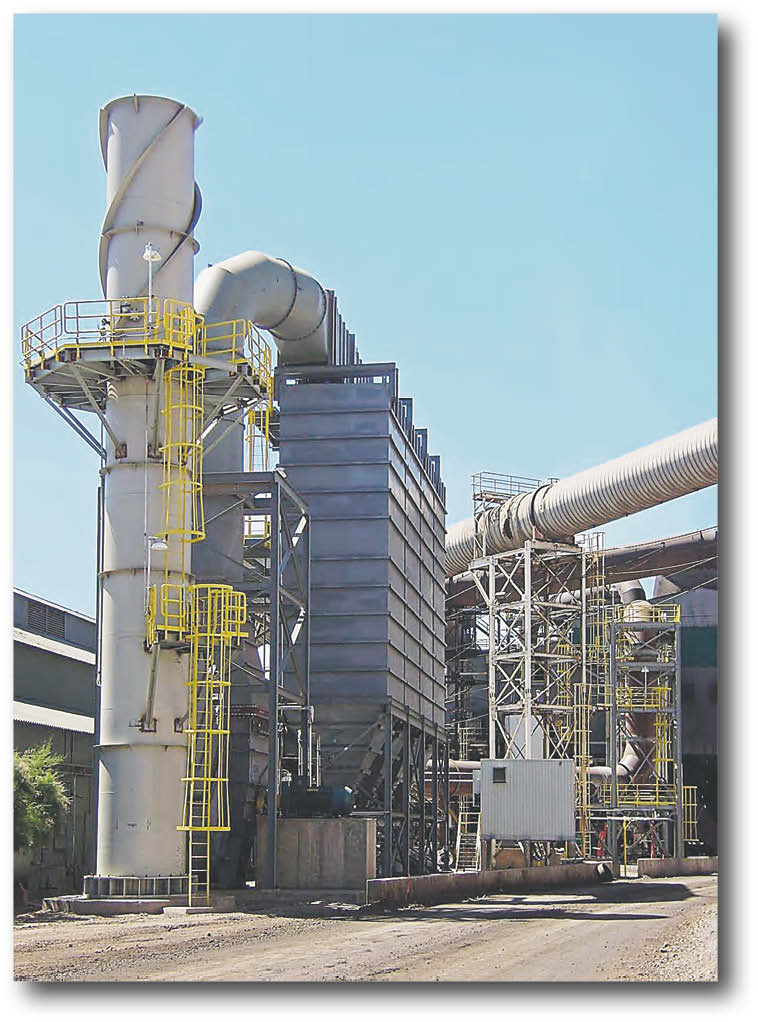

The ASARCO smelter currently operates on a large complex of about 200 acres at the eastern end of the town. Two large emission stacks dominate the horizon. One is 1,001 feet tall and the other is 250 feet tall. There are also several smaller stacks visible at buildings throughout the complex. A large slag pile, a solid glass-like waste material, is on the eastern end adjacent to the town.

But additional upgrades are in the making.

To meet new more stringent emissions rules issued in 2011 by the US Environmental Protection Agency (EPA), ASARCO has drafted plans for a $110 million upgrade of the Hayden copper smelter to bring the apparatus in compliance. Filed with the Arizona Department of Environmental Quality (ADEQ), the project will enable the smelter to meet EPA rules limiting SO2 emissions from 140 ppb (parts per billion) to 75 ppd during a 24-hour period. The Hayden smelter has until Oct. 3, 2018 to meet this standard.

ASARCO’s plan, which it filed on June 24 with ADEQ, describes a converter retrofit project that will replace the smelter’s five current 13-ft. diameter converters with three 15-ft. diameter converters. Also included in the plan are the installation of improved primary and secondary hoods, and an electrostatic precipitator for solids removal prior to SO2 recapture at the smelter’s existing acid plants. Larger ladles (300 cu. ft. instead of 200 cu. ft.) will be installed to reduce the number of hot metal transfers. Additional upgrades will capture secondary gases and direct them to the acid plant for conversion to a sulfuric acid product.

Overall the plan aims to reduce SO2 emissions at the Hayden smelter by 85 percent, with a total SO2 capture rate of 99.7 percent of what is produced during the copper smelting process.

The plans were made public during a meeting of the Arizona House Committee on Energy, Environment and Natural Resources held Aug. 22 at the Gila Community College Pueblo Campus in Globe.

ADEQ is expected to rule on the ARARCO plan early this fall. If approved the plan will then go to EPA for an additional 45-day comment period. With EPA approval, ASARCO could begin work on the upgrades before year’s end.

Work on the converter retrofit will be performed as to not disrupt the operation of the smelter and keep all employees working their regular daily schedules, Aldrich said. The smelting plant must operate within the EPA emission limits by Oct. 3, 2018.

Meeting the standard is important to keep the Hayden copper smelting plant operating and providing employment for residents of the Hayden/Winkelman area, Aldrich added.

This project is worth the investment because demand for copper has remained steady in recent years. Since 2010, copper has averaged around $3.15 a pound, Aldrich noted. This is up from under $1 a pound as late as 2003. Copper continues its traditional uses inside electrical and electronic products and delivering electricity to homes. Only in the outdoor modules of air conditioning systems and heat pumps has copper lost as several manufacturers have switched from copper to aluminum wiring to thwart thieves attracted by high prices for salvaged copper from stripping these modules of copper wire for a fast $70 payoff while ruining $3,000 in equipment.